Description

INDUSTRIAL FLOORING SOLUTIONS

Heavy-Duty Industrial

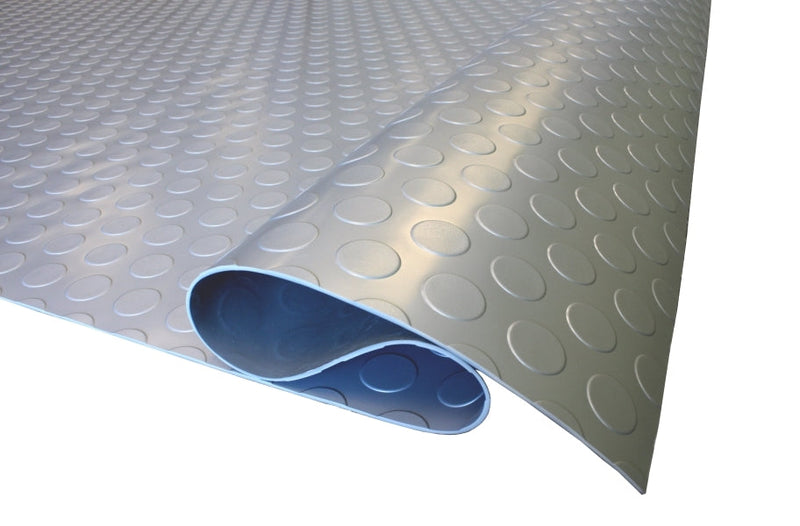

Vinyl Flooring Rolls

Professional-grade non-slip safety flooring engineered for workshops, warehouses, factories & high-traffic industrial environments

Industrial-Strength Performance Where Safety & Durability Are Non-Negotiable

In manufacturing, warehousing, and industrial environments, flooring must withstand extreme demands whilst maintaining safety performance. Our heavy-duty vinyl flooring rolls deliver proven slip resistance, chemical tolerance, and mechanical durability that conventional flooring cannot match.

Specified by facilities engineers, operations managers, and health & safety professionals across manufacturing, logistics, automotive, and industrial sectors for verifiable performance under the most demanding operational conditions.

Engineering Performance Characteristics

Superior Slip Resistance

Textured vinyl surface provides exceptional traction in dry, wet, and contaminated conditions - demonstrably reduces workplace slip incidents and supports HSE compliance obligations

Heavy-Duty Wear Resistance

Industrial-grade vinyl compound withstands forklift traffic, pallet trucks, heavy machinery, and sustained foot traffic - maintains structural integrity for 12-15 years in demanding environments

Chemical & Oil Resistance

Resists degradation from oils, greases, solvents, coolants, hydraulic fluids, and industrial chemicals - maintains performance in contaminated environments where conventional flooring fails

Easy-Clean Hygienic Surface

Non-porous vinyl surface prevents contamination absorption - sweep, mop, or pressure wash for rapid cleaning with minimal downtime and reduced labour costs

Technical Specification

| Material Composition | Heavy-duty industrial-grade vinyl compound |

| Surface Finish | Textured non-slip pattern for maximum traction |

| Supply Format | Roll format - custom cut to length for precise coverage |

| Slip Resistance | High-traction surface suitable for wet & contaminated areas |

| Chemical Resistance | Oils, greases, solvents, coolants, hydraulic fluids, detergents |

| Load Bearing | Suitable for forklift traffic, pallet trucks & heavy machinery |

| Installation | Adhesive-bonded to prepared subfloor - professional installation recommended |

| Maintenance | Sweep, mop or pressure wash - minimal upkeep required |

| Service Life | 12-15 years in heavy industrial environments |

Proven Performance Across UK Industrial Sectors

From automotive manufacturing to pharmaceutical production, aerospace facilities to food processing plants - delivering safety, durability, and operational reliability where industrial performance standards are business-critical

Industrial Applications & Environments

Manufacturing & Production

Assembly lines, machine shops, fabrication areas, quality control zones, production floors - withstands heavy machinery, tooling, and sustained operational demands

Warehousing & Logistics

Distribution centres, fulfilment facilities, cold storage, picking areas, loading bays - handles forklift traffic, pallet movement, and high-volume throughput

Automotive & Engineering

Vehicle workshops, MOT bays, service centres, engineering facilities - resists oils, greases, hydraulic fluids, and mechanical contamination

Food & Pharmaceutical

Food processing, packaging lines, pharmaceutical production, clean rooms - hygienic non-porous surface supports GMP, HACCP, and regulatory compliance

Aerospace & Defence

Aircraft hangars, maintenance facilities, component manufacturing, testing areas - meets demanding performance and safety specifications

Chemical & Process Industries

Chemical plants, refineries, process facilities, laboratories - chemical-resistant surface maintains integrity in aggressive environments

⚠️ Health, Safety & Regulatory Compliance

Engineered to support compliance with Health & Safety at Work Act 1974, Workplace (Health, Safety and Welfare) Regulations 1992, Management of Health and Safety at Work Regulations 1999, and CDM Regulations 2015. High-traction industrial flooring demonstrably reduces slip incidents in contaminated environments - critical evidence for risk assessments, method statements, and HSE inspections.

Industry Standards: Suitable for facilities requiring ISO 9001, ISO 14001, ISO 45001, BRC, and other quality/safety management system compliance.

Installation & Maintenance

Installation Requirements

Subfloor Preparation: Requires clean, dry, level concrete or screed subfloor. Surface must be free from oil, grease, dust, and loose material. Moisture testing and DPM verification essential.

Adhesive Bonding: Full adhesive coverage using polyurethane or epoxy flooring adhesive. Professional installation recommended to ensure proper bonding, seam welding, and warranty compliance.

Curing Time: Allow 24-48 hours before light traffic, 72 hours before full operational loading. Consult adhesive manufacturer for specific cure schedules.

Maintenance Protocol

Daily: Sweep or vacuum to remove loose debris and metal swarf. Spot-clean spills immediately to prevent slip hazards.

Weekly: Mop with neutral pH detergent or industrial floor cleaner. For heavy contamination, use degreaser or alkaline cleaner.

Periodic: Pressure wash or scrubber-dryer clean for deep cleaning. The non-porous surface resists staining and bacterial growth - maintains hygienic performance with minimal intervention.

Total Cost of Ownership Analysis

Reduced Maintenance Costs

Easy-clean surface reduces labour hours and cleaning chemical consumption by 40-60% vs. porous flooring - significant operational savings over 12-15 year lifespan

Lower Accident & Insurance Costs

Slip-resistant surface reduces workplace accidents, compensation claims, HSE investigations, and insurance premiums - demonstrable risk mitigation supports duty of care obligations

Minimal Downtime

Rapid installation and fast cure times minimize production disruption - phased installation enables continued operations during floor replacement projects

Extended Service Life

12-15 year lifespan in heavy industrial use vs. 3-5 years for conventional flooring - defers capital expenditure and reduces lifecycle replacement costs

PROFESSIONAL SUPPLY & INSTALLATION

Trade Pricing & Technical Support Available

Competitive rates for facilities management companies, industrial contractors, manufacturing groups & multi-site operators. Credit terms for approved accounts. Free site surveys, material calculations, and installation specification support provided.

Frequently Asked Questions

What roll widths are available?

Contact our technical team for available roll widths and custom cutting options. We provide material take-offs and coverage calculations based on your facility dimensions and layout requirements.

Can this handle forklift traffic?

Yes. The heavy-duty vinyl construction is engineered for forklift traffic, pallet trucks, and wheeled equipment. Proper subfloor preparation and adhesive bonding are essential for maximum load-bearing performance.

Is professional installation required?

Professional installation is strongly recommended to ensure proper subfloor preparation, adhesive coverage, seam welding, and warranty compliance. We can recommend approved installers in your region.

What chemicals will it resist?

The vinyl compound resists oils, greases, solvents, coolants, hydraulic fluids, and common industrial chemicals. For specific chemical exposure, consult our technical team with details of contaminants and concentrations.

How long does installation take?

Installation time depends on area size and complexity. Typical warehouse bay (500-1000m²) requires 3-5 days including subfloor prep, adhesive application, and curing. Phased installation minimizes operational disruption.

What's the expected lifespan?

12-15 years in heavy industrial environments with proper installation and maintenance. Lifespan depends on traffic intensity, load types, chemical exposure, and maintenance regime. Significantly outlasts conventional industrial flooring options.